Products

-

Acoustic cloud ceiling panels – Circle

Huamei’s acoustic clouds are a tasteful and unobtrusive option for reducing reverberations and improving intelligibility, in any space. The range of unique shapes and sizes on offer opens the door for architects, designers and installers to present clients with creative solutions that are bold, yet architecturally pleasing.

-

Fiberglass Tissue Mat-HM COLOR

HM Colored- Beautiful colors can be painted on our fiberglass Tissue

Our Fiberglass tissue can creat different designs, the best-selling and most popular design is HM000A, its regular density is 210g/m2, of course 100g/m2-300g/m2 density also available, like 120g/m2, 150g/m2, 180g/m2 and so on.

-

Fiberglass Tissue Mat-HM800

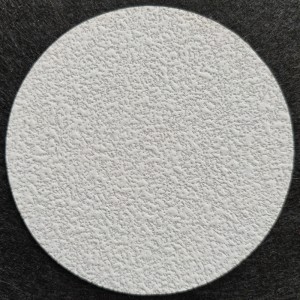

HM800-Acoustical Fiberglass Texture Tissue Mat

Used in all kinds of ceiling surface, wall panels surface decoration,

with sound absorption and noise reduction,

heat insulation,antibacterial and mildew.

-

Fiberglass Tissue Mat-HM700

HM700-Great Acoustical performance Glass Fiber Texture Tissue mat

High sound absorption

Excellence in fire-retardant

Good cover capability

Smooth and soft surface

Fiber uniformly dispersed

Anti-fouling(oil stain)

Directly use after lamination

-

Fiberglass Tissue Mat-HM600

HM600 -Perfect White Painted Design Fiberglass Texture Tissue mat

-

Fiberglass Tissue Mat-HM000B

Black Fiberglass tissue mat for glasswool Ceilings in Cinema -HM000B

For black color glass fiber tissue, we have two different processing techniques.

One is coated tissue, density 180g/m2;

Another is Soaking tissue, density 80g/m2.

-

Fiberglass Tissue Mat-HM000A

The popular and hot sell Fiberglass coated facing tissue mat- HM000A

This white spray design fibergass coating tissue mat HM000A is our popular and best selling item.

Regular density is 210g/m2, Of course other densitys can be customized, like 120g/m2, 150g/m2, 180g/m2, 250g/m2 and so on.

-

Fiberglass Tissue Mat-HM000

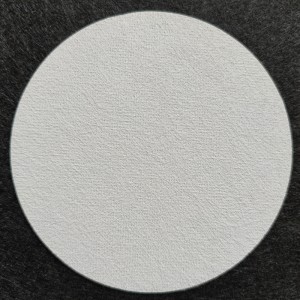

Ideal fiberglass base tissue as surface decorative material -HM000

The design of HM000 is natural front tissue, it is considered as base tissue.

The density usually be made 40-60g/m2.

-

Fireproof film fiberglass film tissue mat for acoustic ceiling surface decoration

Product Description Fiberglass Roofing Tissue is a new excellent basic material used in the surface of ostentations material of mineral wool,fiberglass ceiling board.It is used in public entertainment places, star-hotel, shopping center, conference hall, office building and resident house. Fiberglass Tissue/Mat Used in all kinds of ceiling surface ,wall surface decoration,with sound absorption and noise reduction,heat insulation,antibacterial and mildew. Sound Absorrtion &... -

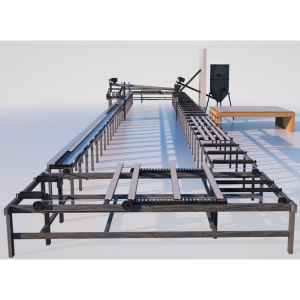

PVC gypsum board production line

PVC gypsum ceiling board production including laminated gypsum ceiling board machine, plasterboard cutting machine, gypsum ceiling board packing machine and so one.

-

GRG fiberglass reinforced gypsum ceiling

1. Actomatic GRG gypsum ceiling has high degree of automation, simple equipment operation, only need to carry out correct operation training

to work, save labor, reduce labor costs, and improve work efficiency.

2. There is no limit to the production site, as long as the production site is safe and the facilities are complete

with water and electricity to work.

3. Custom processing, can be customized according to customer needs, only need to provide the size of the

product. Let the product quality be guaranteed, avoid waste, and make the product processing effect better.

4. The composition of production materials is simple and there are no regional restrictions.

-

Gypsum cornice production Machine

Process flow

Automatic mold cleaning—automatic mold—automatic feeding grouting—vibration—automatic threading—automatic hanging net—mold forming—moulding—automatic return, and only 7 people can meet the production needs.